Woodshop Musings

5 Traditional Joinery Techniques

Brian Muse

October 1, 2021

There are so many ways to join two pieces of wood together. When I first started woodworking, I did the easiest joint I could make - the Butt Joint. This is simply butting two boards together using glue, nails and/or screws. Over time, my tools and skills improved, and I began to master various traditional joinery methods.

What are Traditional Joinery Methods?

Traditional Joints primarily use only wood, designed in strategic ways, to join two or more pieces of wood together. These different joint designs have pros and cons depending on the application.

Why Should You Care?

If you don't like wasting money and want quality furniture, then you should care. The strength and longevity of a piece of furniture is determined by the types of joints used. When you're looking at furniture, take a moment to notice what joinery methods are used. It's easy to quickly check - open a drawer, door, or look under it and find out how it was built. Traditional joinery methods take more care, skill and time to implement. This is one of the reasons why the cost of custom furniture

is normally higher.

Why are Traditional Joinery Methods Important?

Traditional joinery methods have been used for thousands of years and have stood the test of time. The type of joint used directly impacts the durability and longevity of an item. The joint can determine if the item will stay together for 3 minutes or 3000 years. The forces that can be applied to a joint are multi-directional. The more a joint can protect against multi-directional forces, the longer the joint will last. Good wood joints also allow the joint to expand and contrast with humidity and temperature changes. Joints only secured with screws or nails, can work loose over time due to climate variabilities.

Some of the Traditional Joints I Use

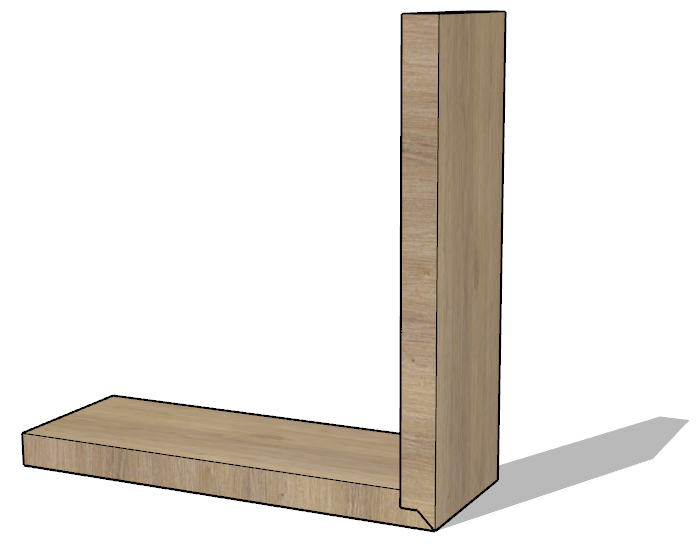

(1) Lap Joint

(2) Dado Joint

(3) Box Joint

(4) Mortise and Tenon Joint

(5) Mitered Rabbet Joint

In the early 1800's, Shaker chairs featured wooden ball and socket feet on the back legs to keep the leg bottoms level while tilting. In the original design, the wooden ball foot was secured to the leg with a leather strap that threaded through the foot and into the leg. This design allowed the feet to be held firmly to the bottom of the leg, but not too firm to allow the chair to tilt backwards.

Whether you want to get into woodworking or just a homeowner, a miter saw is a perfect tool to have around. It might seem like you need a full woodshop to get into woodworking, but you really don’t. When I started woodworking, the only tool I had to cut boards was a miter saw. This is one of the best basic tools to have in your garage. I have the 12” Double-Bevel Sliding Compound Miter Saw (DWS779) . I would recommend this saw, if you’re looking to buy one. There are 3 main things you can do using this tool: Straight Cross-Cut Angled cut Beveled cut 1. Straight Cross-Cut

About Neighborhood Favorite Awards Local businesses are the cornerstone of thriving neighborhoods. So every year, Nextdoor runs a campaign called Neighborhood Favorites, to highlight beloved businesses in neighborhoods. This is the only local business award voted solely by neighbors who know. Only 2% of all businesses on Nextdoor are crowned a Neighborhood Favorite each year, which means winning is a pretty big deal! Neighborhood Favorite Award We were awarded the 2021 Neighborhood Favorite Award on August 17, 2021 in 4 neighborhoods. In Indianapolis: Meridian Hills East , College/Monon Trail Corridor and Woodcroft by the Monon . In Zionsville: Royal Run .

When people think of custom furniture, they might assume that it's too expensive. If you compare the price of an end table from a big-box store with a custom end table, the custom end table is sure to cost more (at first). In reality, you will spend more money buying Fast Furniture than Custom Furniture. Fast Furniture is designed, manufactured and mass-produced to be as cheap as possible. Particleboard is normally used which is made from sawdust, wood chips and urea-formaldehyde glue (a human carcinogen). Particleboard warps and bubbles when wet, brakes easily, and contains harmful toxins. As a result, this kind of furniture only lasts a few years on average. " Buy cheap, buy twice"

Red Oak has a bending strength of 14,300 pounds per square inch. To put that into perspective, a helicopter, school bus, and semi-trailer weigh about 14,000 pounds. Oak is super strong, and it's not going to want to bend without some serious convincing. Why am I wanting to bend solid oak? Well, a client wanted a high-quality, round end table but was unable to find exactly what she was looking for. I created a 3D sketch of what she wanted, which included curved sides right under the table top. I needed to create 4 sides with a 10" radius with one of those sides acting as a drawer front.

I recently finished up one of my most challenging projects to-date - A solid wood, round end table . It involved steam bending solid ¾" oak for the sides, a lattice pattern on the top and traditional joinery methods throughout. I couldn't help but reflect on when and how my woodworking journey began.